This beautiful chess table is a Christmas present that I made for my son Max. He loves chess and it looks like he is actually quite good at it; using the internet to play chess with like minded people. But I think, seeing and feeling actual chess pieces enhances the experience, therefore that table. And as all my woodwork projects, this one too starts with a detailed sketch:

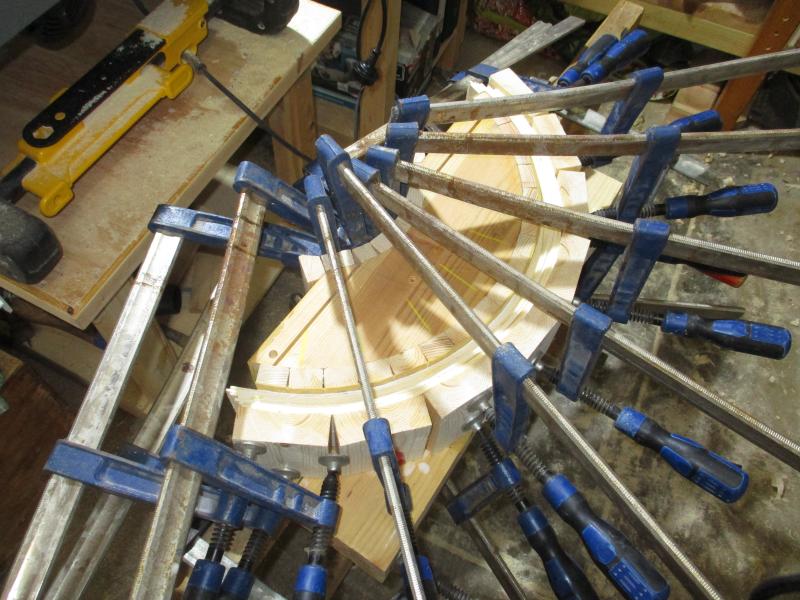

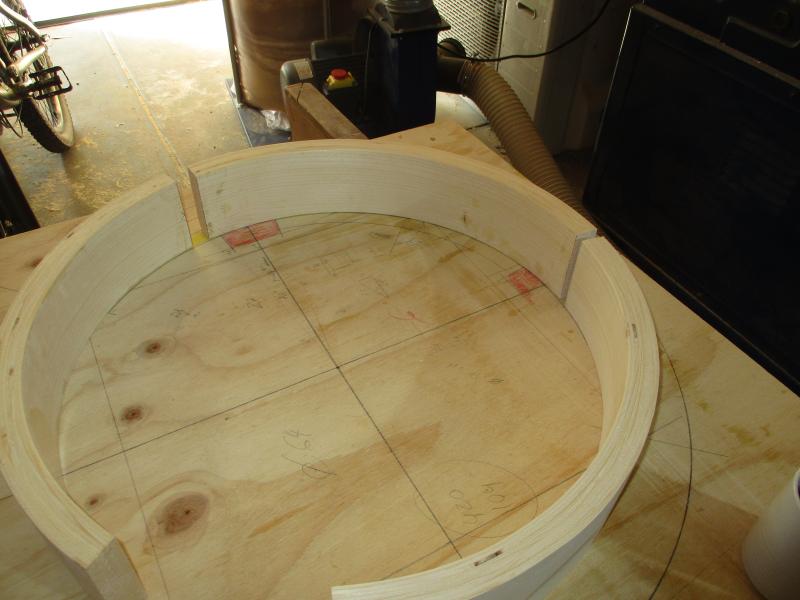

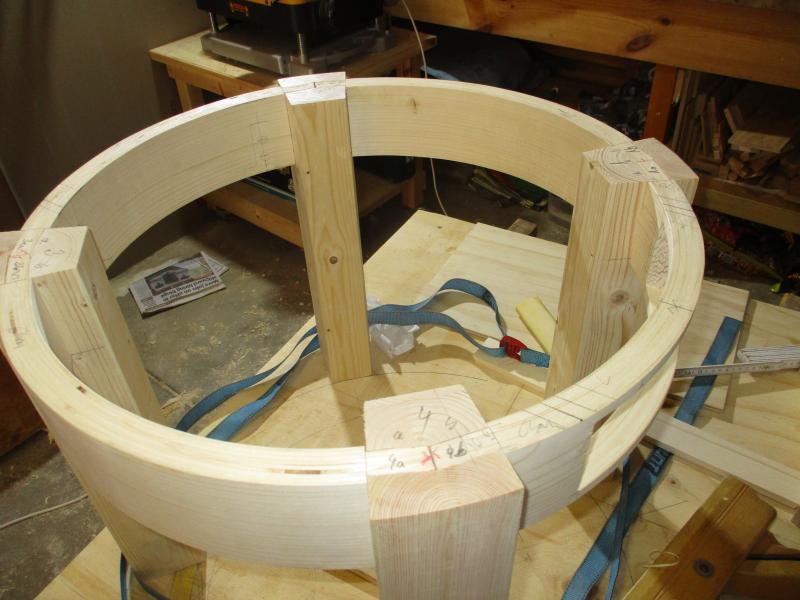

Of course there was a little bit more to it. I actually made a better drawing in scale 1:1 on a sheet of plywood. It shows the table frame from top. As the table top is round, the table frame needs to be round too. Here is how it's done:

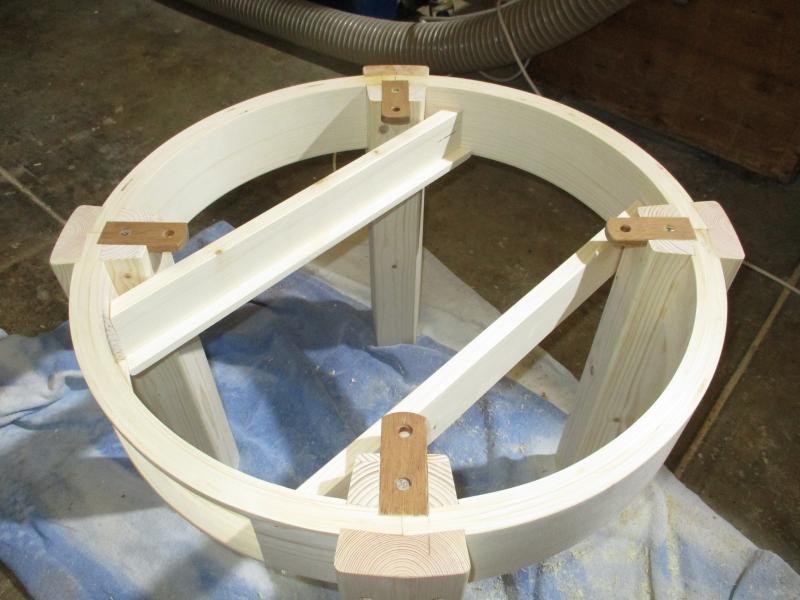

OK, looks like this didn't work as planned. All it required was one of Adelaide's heat waves and the chess board cracked. A pity. All my joints have been sturdy and stable as expected, only the wood itself couldn't withstand the forces created by it's shrinking. So, this second part is all about the new solution - the board float-mounted in the frame.