We bought our home almost fifteen years ago and it was old af at that time already (I think it has been built 1974). Having to pay off the mortgage didn't particularly help with renovations, so we postponed everything expensive as much as possible. But our roof was leaking like a sieve all the time which didn't really help either. I did small fixes over the years but the roof was at the brink of collapse this year. So, we bit the bullet and did a thorough renovation during our summer vacation.

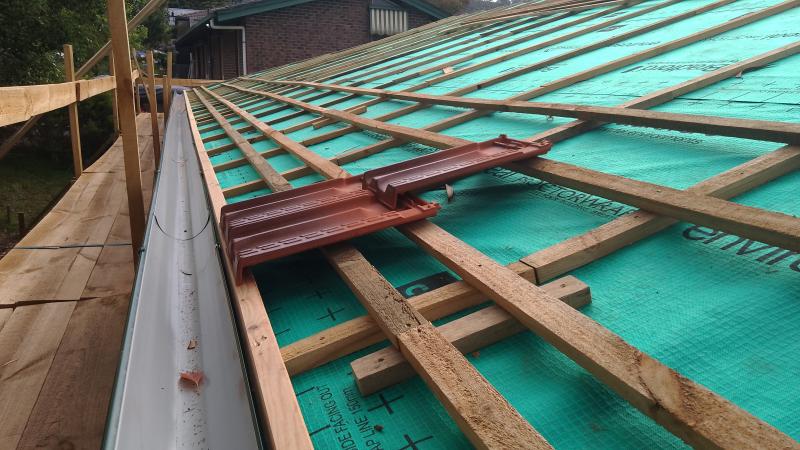

Not only did we renovate though. We also tried to improve the standard of our roof, adding roof-boarding, roof-sarking, air battens and a ventilation system to it.

Our suppliers:

ADA (flashings, etc.)

Tools (Compressor, Nail-gun, etc) from

Totaltools

Bunnings Parafield

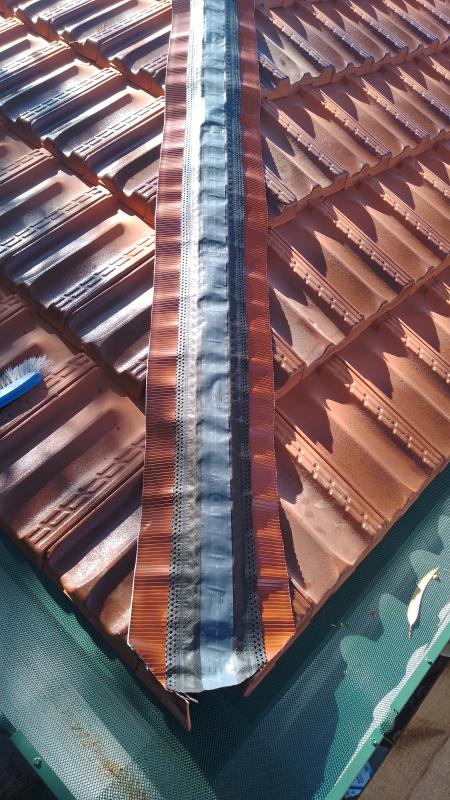

I bought a lot of sheet-lead for the flashing and was wondering if there is something easier to work with. And there is, I just didn't know at the time:

Wakaflex could be worth a try.